Sustainable Solutions: A Push Toward a Circular Economy

How a blue loan in Romania is helping safeguard natural resources

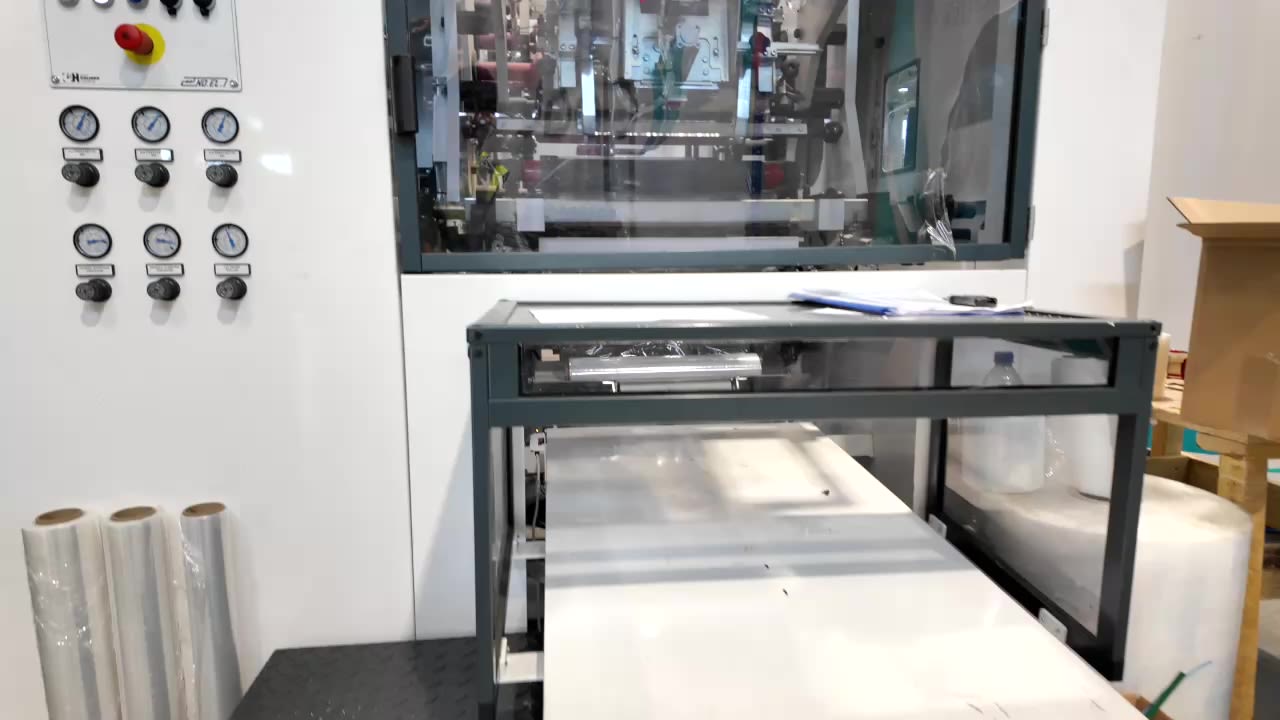

In Bistrița, northern Romania, a hangar-sized factory floor is filled with spotlessly clean machinery which is linked together by gleaming silver pipes. Recently opened, the Opal Stretch Film factory is predominantly automated, with the whistle and buzz of technology filling the air. The smell of plastic hangs heavy, and a strong warmth emanates from the humming machines.

The large spinning rollers generating heat in this factory produce stretch film. Ubiquitous for wrapping luggage at airports around the world, the product is used for a wide spectrum of applications, from securing pallets in warehouses to ensuring that retail products remain pristine during transit.

Part of the TeraPlast Group, the Opal factory is the latest addition to Eastern Europe’s largest plastic polymer processor. TeraPlast is not only focused on creating industry-leading products: sustainability also dominates the company’s corporate goals.

Over 80 percent of the technological water used by TeraPlast is now recirculated. In Bistrița, the wastewater from production passes through two treatment plants in the TeraPlast Industrial Park before being discharged into the Sieu river, ensuring plastics are kept out of local waterways.

TeraPlast’s products also use up to 30 percent recycled material, a key pillar of the company’s goal to reduce its impact on the environment by developing products from environmentally friendly materials and contributing to a circular economy transition.

The use of recycled raw materials has steered TeraPlast’s development strategy for over five years, both through the company’s direct involvement and investment in recycling activities, and through the purchase of recycled materials from the market.

This philosophy has filtered down from the top. “When it comes to sustainable production, TeraPlast has always been ahead of the curve,” says CEO Alexandru Stânean.

From pollution to progress

Because of its unique, durable properties, plastic has become essential to many facets of modern society. But the production, consumption and disposal of plastic can often result in significant negative impacts on society, the environment, and economy.

Plastic pollution in the world’s waterways is a global problem. It is estimated that every year 19-23 million tons of plastic enters aquatic ecosystems, polluting lakes, rivers and seas.

This pollution negatively impacts millions of livelihoods, impedes food production capabilities, and affects social well-being. It can also have negative effects on ecosystems, altering habitats and natural processes, in addition to reducing the ability to adapt to climate change shocks. The global cost of plastic pollution is estimated at $20 trillion, with packaging accounting for 40 percent of all waste.

“In Romania, plastic waste has become a major environmental problem,” says Monia Martini, Senior Project Manager for World Wildlife Fund for Nature (WWF) Romania. “The first to suffer are local communities and their economies.”

A constant presence in the natural environment, a WWF study has shown that 56 percent of Romanians believe that there is too much waste in nature, which is having a negative impact on both the environment and local communities.

“In addition to the impact on ecosystems and human health there is also a cascading economic impact on services such as ecotourism,” she adds. “For Romania, it is important to acknowledge that plastic pollution is a complex problem, and that a systemic approach is needed towards finding the right solutions.”

“To achieve this, it is vital for the private sector to act quickly to prevent by transforming its production, distribution and waste management systems,” says Martini.

Sustainability meets industry

The Romanian stretch film market consists of approximately 30,000 tons annually. Currently imports account for 51% of this demand. With an annual production capacity exceeding 14,000 tons, the Opal factory has the potential to entirely replace these imports with high-quality, locally produced goods, manufactured using cutting-edge equipment.

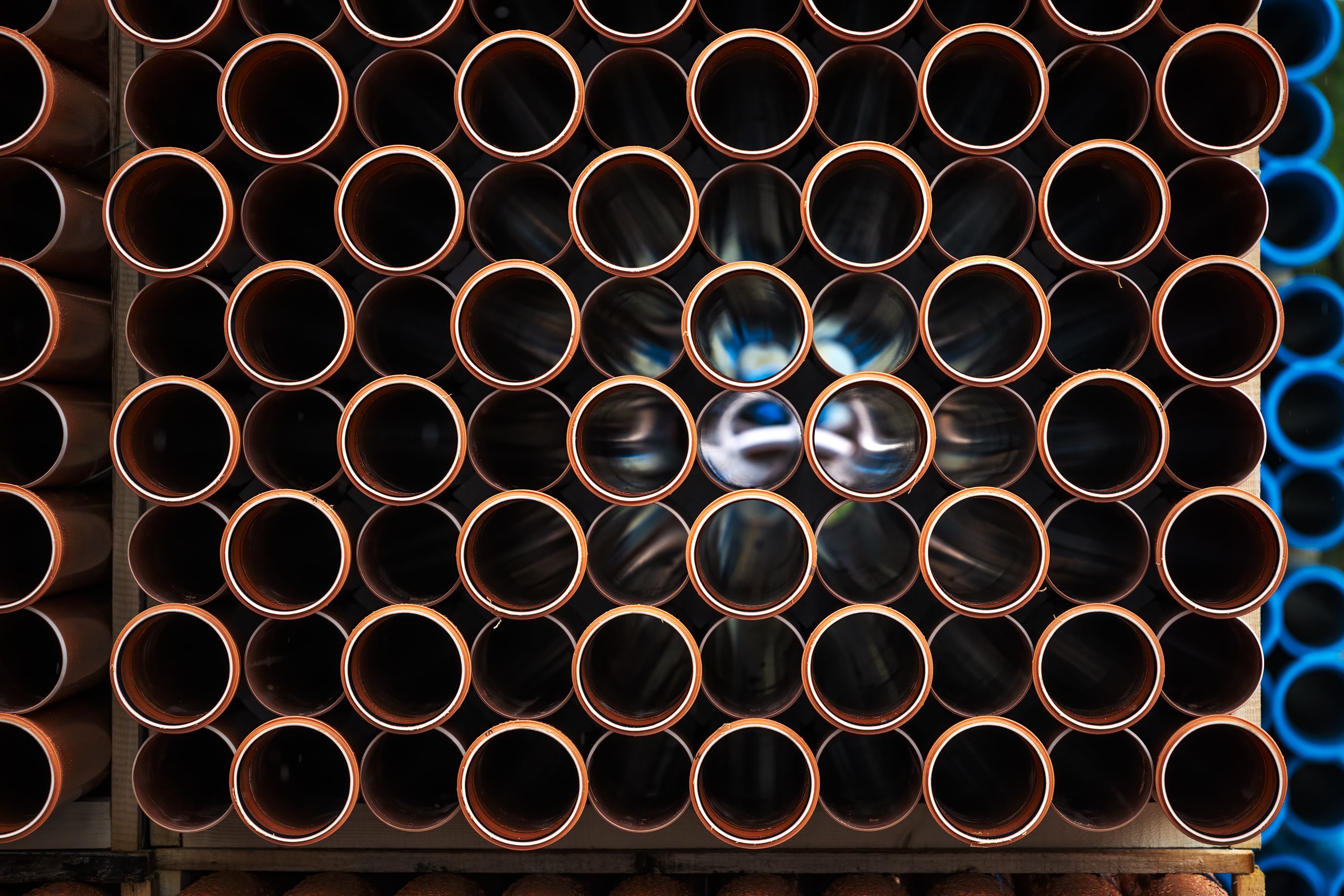

The capacity of the new Opal factory in Bistrița is just one element of a robust TeraPlast Group footprint across Romania. With over 125 years of history, TeraPlast has grown from a producer of ceramic tiles to the largest plastic polymer processor in Eastern Europe. This journey has not been achieved without support.

Funding for TeraPlast’s Opal factory was provided through a €16 million blue financing loan from Banca Transilvania SA, the largest bank in Romania and TeraPlast’s largest financier.

TeraPlast’s blue loan is part of an emerging area of financing known as ‘blue finance’. This financing requires businesses to develop their products and practices within the lines of a sustainable water economy to safeguard access to clean water, protect underwater environments, and reduce plastic pollution. It also allows financial institutions to mobilize the private sector to unlock trillions of dollars for projects which can then become a key pillar in preserving and growing clean water resources.

“Supporting private sector growth whilst reducing issues such as plastic pollution and promoting the transition to a circular economy, is a major challenge,” says Vittorio Di Bello, IFC's Regional Industry Director for Financial Institutions in Europe and Latin America and the Caribbean. “Blue finance provides the funding to support this transition whilst also protecting water quality and availability in countries like Romania.”

In 2022, IFC issued its first blue financing loan in Central and Eastern Europe. The landmark €100 million loan was provided to Banca Transilvania to improve water management practices including sustainable manufacturing, tourism, fishing, sustainable agricultural irrigation, and to contribute to the sustainability of the ocean and freshwater resources.

“For Banca Transilvania, being a pioneer in blue financing has allowed us to focus on reducing the impact of plastics on water quality and raise awareness amongst small and medium sized businesses in the country who are transitioning to a sustainable, circular economy,” says Crymhylde Galos, Deputy Manager EU Programmes and Green Lending at Banca Transilvania.

Taking the lead in this emerging class of blue financing is one benefit from Banca Transilvania’s more than 20-year relationship with IFC. Spanning over 16 investments, the relationship has witnessed Banca Transilvania’s growth from a small regional bank to the largest bank in Romania. It has also made Banca Transilvania the ideal partner to help introduce blue finance to Central and Eastern Europe.

“Thanks to IFC’s support we have introduced blue finance to our clients, encouraging economic growth while supporting the transition to a circular economy, and protecting our precious natural spaces in Romania,” says Ömer Tetik, Chief Executive Officer of Banca Transilvania.

As with any nascent sector, to ensure even and coordinated growth, guidelines are required. In 2022, IFC published the Guidelines for Blue Finance which have set global standards, provided advice on blue project eligibility criteria, and encouraged other institutions to embrace further investments that protect global water resources.

Before lending to any business, Banca Transilvania first conducts an Environmental, Social, and Governance (ESG) assessment. This assessment reviews company operations, examining how the loan will be used and ensuring that the correct criteria are met. The business is then monitored throughout the length of the loan to ensure that standards are maintained.

Looking Forward

Thanks to their strong sustainability goals, TeraPlast Group has met these high ESG standards. Alexandru Stânean, TeraPlast CEO, says that Banca Transilvania’s assistance has been transformative: “without their support we wouldn’t have come so far so fast”.

Stânean explains that TeraPlast is a signatory to the United Nations Global Compact, a voluntary initiative based on CEO commitments to implement sustainability measures. These sustainability targets, he says, are a key strategic priority for TeraPlast to fulfill its mission to provide efficient solutions, not just for the people of Romania, but for the environment too. Thanks to Banca Transilvania’s blue loan, and the company’s own sustainability standards, Stânean says, TeraPlast is determined to “put their own house in order”.

Learn More about Blue Finance