No Glass Ceilings

How a Tanzanian glass maker is leading the way in sustainable manufacturing

On a dusty, sunbaked street in Dar Es Salaam, Tanzania, workers are gathering on their breaks to chat, play checkers, and enjoy ice cold drinks.

Devotha Kutika is helping quench their thirst, doing brisk business selling a variety of juices and well-known soft drinks from her market stall to customers who mainly work at the nearby port.

“I sell about 50 bottles a day, even more when the port is very busy,” she says. “People definitely seem to prefer glass bottles to plastic and the glass bottles are cheaper to buy too for the same amount of drink.”

In Tanzania, those who prefer drinking from glass can largely thank KIOO Glass for providing the bottles. The local manufacturing company, situated on a sprawling 24-acre plot on the edge of Dar Es Salaam, was founded in the early 1960s, not long after Tanzania gained independence.

KIOO (which means glass in Swahili, an official language in Tanzania) is the largest glass manufacturer in East Africa and one of Tanzania’s biggest private sector companies, employing more than 600 people directly and supporting about 2,000 indirect jobs.

The company is something of a glass powerhouse, producing about 1 million bottles a day from superhot furnaces that run around the clock, 365 days a year. Even so, KIOO can’t keep up with demand from bottlers and partnered with IFC to realize its expansion plans.

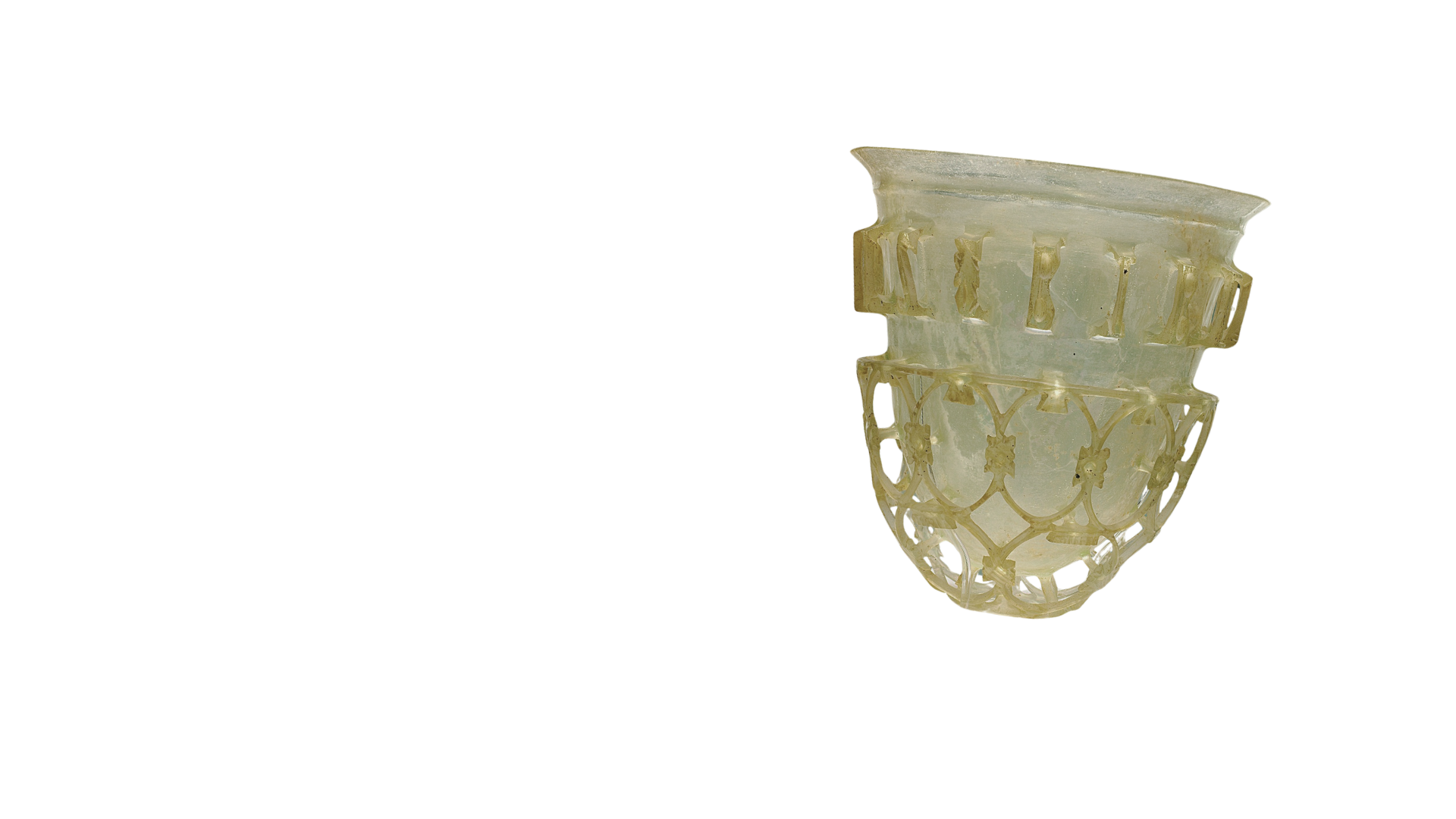

Kioo's glass furnace.

Kioo's glass furnace.

In May 2024, IFC provided KIOO with a loan of up to $45 million to help the company expand production, including by building and operating a new furnace. This follows earlier IFC financial support for KIOO, including a $10 million loan made in 2021 at the height of the COVID pandemic to help the company at a perilous time for manufacturers.

With financing from IFC, KIOO has steadily grown its business and today exports to more than 100 customers—and growing—in 14 countries in East and Southern Africa, including big names like Coke and Pepsi.

In Tanzania, still KIOO’s largest market, demand for refillable glass containers is expected to grow by 10 percent annually over the next five years, reflecting the resilience of an ancient—and infinitely recyclable—material in a world increasingly dominated by plastic.

“It’s not possible to grow manufacturing incrementally—you can’t build and run half a furnace—so we are grateful for a partner like IFC. We aim to increase our capacity by about 70 percent…We know the demand is there and now we will be able to match it.”

Kumar Krishnan, KIOO’s Director

According to historians, glass bottles have been with us since at least 1500 BC when the Mesopotamians introduced them.

While plastic only began appearing on store shelves in the 1950s and 60s.

In only a few short decades, however, plastic has become the dominant packaging material for water and various other beverage bottles thanks to its cost effectiveness and the ease of transporting and storing it.

Sustainability

Even so, glass remains popular and prized by bottlers and consumers, especially given that plastic can leech and affect the flavor of beverages and foods. And while there is much debate around whether glass or plastic is ultimately better for the environment, there is no arguing that glass can be produced and recycled sustainably and in ways that prevent empty bottles from ending their lifecycles in landfills.

“We are committed to expanding production and satisfying our customers’ needs but are also always looking to do it in a sustainable way that minimizes environmental harm,” Krishnan said. “We already have a robust recycling program in place, but our goal is to green our production, reduce waste, and promote recycling even further.”

KIOO embraces sustainability even at the very beginning of the glass making process. Sand (silica) is the main ingredient in glass and KIOO sources from its own quarries about 35 kilometers outside Dar Es Salaam. On land where it has exhausted the supply of sand, the company plants trees and other vegetation, rewilding the landscape or turning it into a farm.

KIOO’s glass bottles themselves are strong and durable and equal to standards set in Europe or North America. An important aspect of glass’s green credentials is the fact that bottles can be collected, washed, sterilized, and used again and again.

In Tanzania, SBC is a major purchaser from KIOO. The company fills more than 816 million KIOO-made bottles a year with Pepsi Cola and other brands such as 7UP and Mirinda soft drinks, employing about 1,320 full time employees across their four plants in Tanzania.

“We reuse our bottles an average of 18 times, which at that level makes them more economical than plastic,” said Paul Richards, Chief Executive Officer for SBC Tanzania. “We are very much a glass business in Tanzania, but it wouldn’t be economical or practical for us to use glass if KIOO wasn’t just down the road producing such a high-quality product,” he said.

KIOO collects broken or damaged bottles from SBC—and its other clients—and returns them to a vast cullet yard adjacent to its manufacturing plant, where it cleans, crushes, and then fashions them into new bottles, ready to be filled again.

“Every bottle we produce is 40 percent recycled material. We launched a major recycling program back in 2015, but we know we can do more to reduce waste." - Kumar Krishnan, KIOO’s Director

Bigger recycling ambitions

KIOO already collects tens of thousands of breakages and rejected bottles from its partners every month, but the company is setting its recycling ambitions much higher.

In Tanzania, and with advisory support from IFC, KIOO is seeking to almost double the amount of glass it recycles, from 19,700 tons to 35,700 tons annually, equivalent to more than 100 million bottles.

The strategy involves collecting as many empty bottles as possible that are sold in bars, shops, stalls, and restaurants in Tanzania—bottles that would otherwise most likely be thrown away, discarded on streets, or collected for landfills.

“We are missing out on many of the bottles we could be collecting, but with IFC, we are exploring how and where we can intercept bottles before consumers throw them away,” said Krishnan. “This is an important environmental strategy, but it also makes financial sense to reuse as much glass as we can.”

KIOO and IFC have determined that restaurants and bars are the best point of interception and the biggest opportunity for recycling. KIOO is planning to trial establishing glass deposit containers at various retail locations in and around Dar Es Salaam and then regularly collect and return the glass for cleaning and melting.

If KIOO can reach its recycling targets, the company estimates it would save 4080 tons of CO2 emissions annually—not to mention removing millions of bottles from streets and landfills.

“Our longstanding partnership with KIOO reflects IFC’s twin commitments to industrialization and sustainability in Africa,” said Mary Porter Peschka, IFC Regional Director for Eastern Africa. “KIOO is creating skilled jobs and supporting supply line development in Tanzania and beyond, while also showing that this can be achieved in conjunction with a strong focus on protecting the environment.”

Back at Devotha’s market stall, the lunch break is ending and the workers are rushing off again to resume their shifts. Abdullah Pazi finishes the last of his soft drink and sets the glass bottle back on the counter.

“I prefer glass,” he says, when asked why he chose glass over plastic. “I always think it tastes better in glass, especially when it’s a very hot day.”